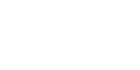

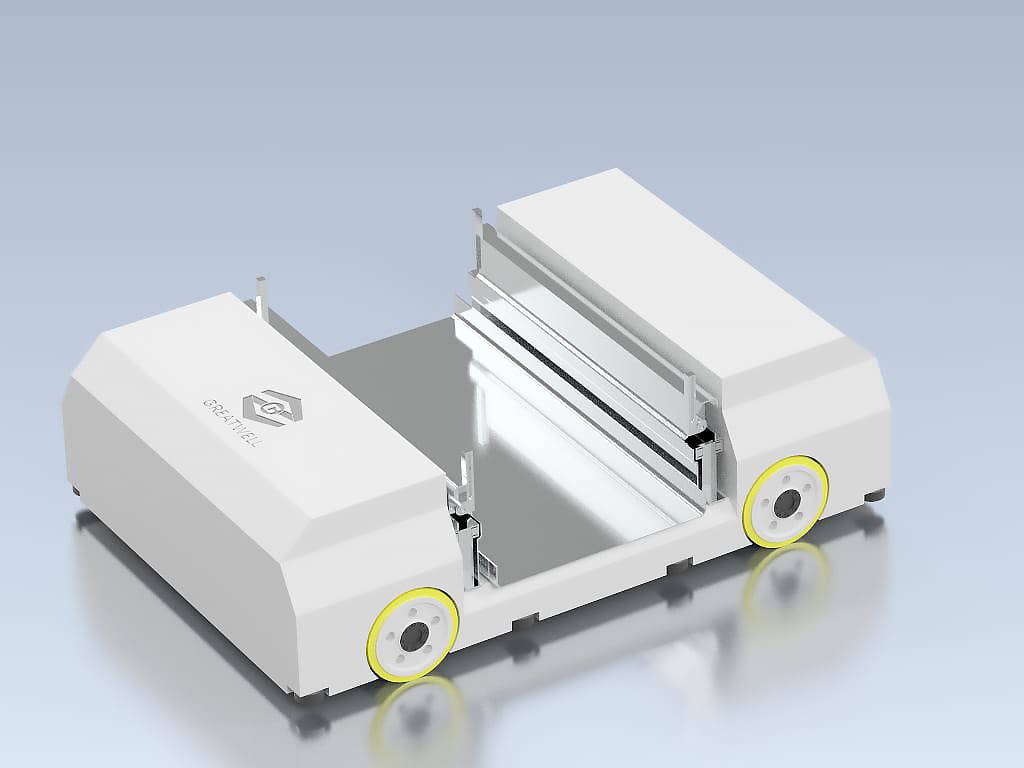

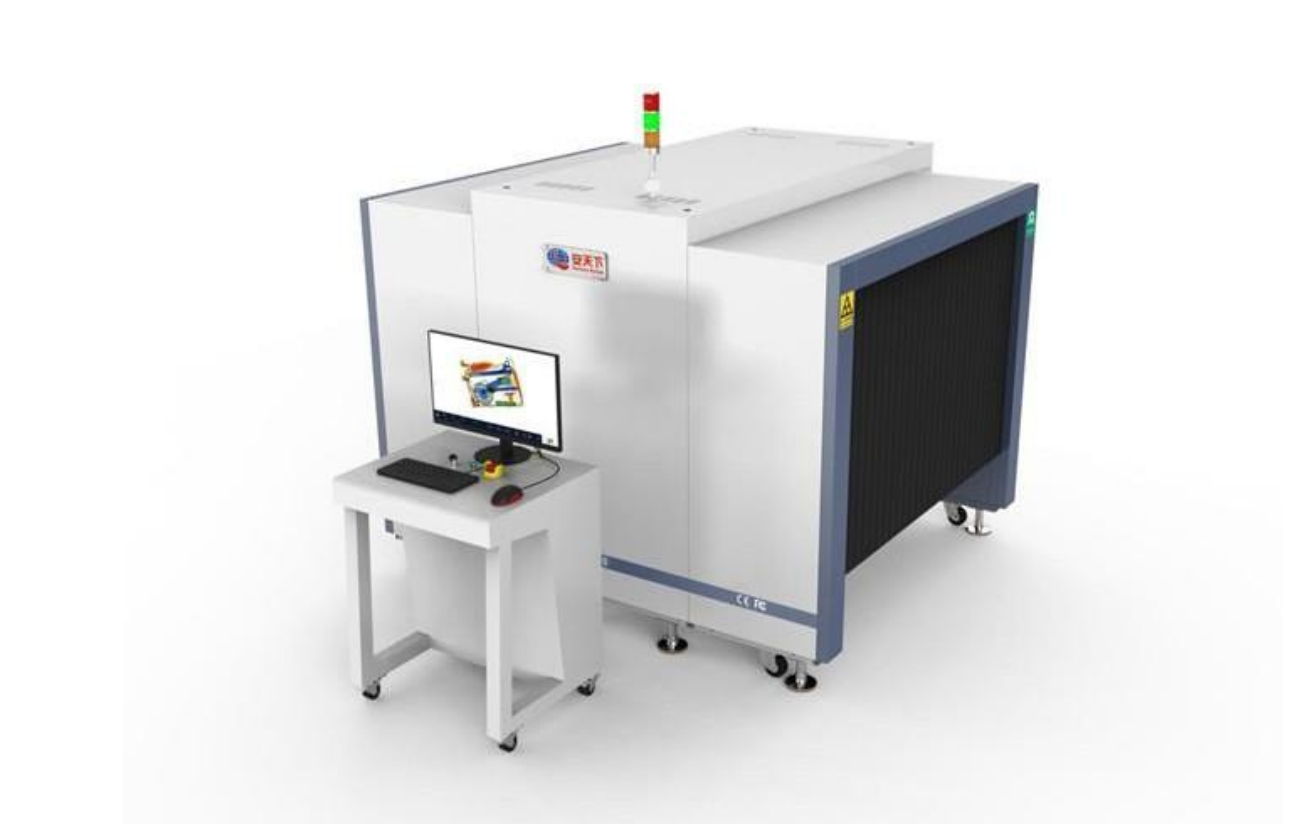

Multi-layer shuttle car adopts intensive storage instead of attic storage, which greatly reduces the storage land area. The automatic system of a multi-layer shuttle car is adopted to realize unmanned operation in the storage area. In the project, laneways, robots, and floor-changing elevators are used to realize the storage, storage, and floor changing of multi-layer robots through system scheduling. The principle of centralized box grouping, centralized shelving, and instant picking is adopted for material operation. The form of an automatic transmission is adopted in the storage and picking room to truly realize the mode of picking goods for people. The whole information process is truly connected, from SAP to the barcode system to the WMS and WCS of the multi-layer shuttle system, realizing seamless data connection, So as to realize the information management of all materials in the warehouse area, warehouse location, bin, pallet, and carton. Sorting and storage adopt system scheduling and ergonomic design to reduce the working pressure of people and reduce the error rate of manual errors. Real-time tracking of all goods and full process monitoring of all equipment operation status